A dust collector is a class of air pollution control equipment used in plants, factories, warehouses, and other commercial or industrial setups to meet ecological and place of work safety requirements. These requirements are designed to protect employees and the surrounding environment.

During production and manufacturing, an efficient dust collector machine reduces, controls, and removes harmful matter and gases fumes produced by manufacturing process or released into air and the environment surrounding the production facility.

To maintain and enhance the air quality in the working area, the equipment has been particularly built to disinfect and filter harmful dust and fine particle contaminant matter that has been discharged into the atmosphere.

Dust Collectors With Shaker Mechanisms

Often known as shaker dust collectors, dust shakers are a baghouse system. Either the system cleans the baghouse offline while the airflow is momentarily stopped, or it divides it into several portions. A partitioned design into compartments enables continual cleaning of the unit while also allowing the individual compartments to be shut down and serviced in isolation. Foundries, mills, power plants, the mining sector, and smelting industries are some of the businesses that often use these machines. They are also used in locations where dry materials are kept in silos and other bulk storage containers.

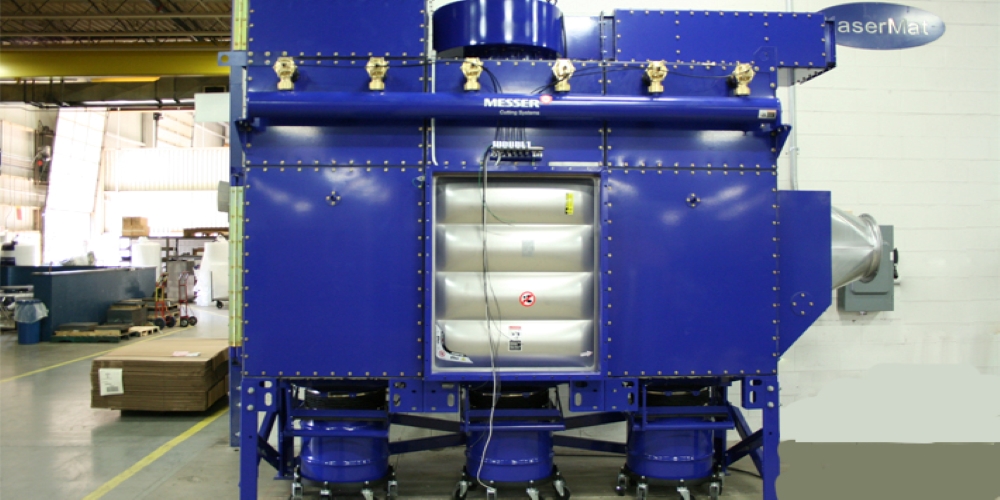

Dust Collectors That Use Pulse Jets

Pulse jet dust collectors are an additional kind of baghouse system that may be purchased in many configurations to accommodate a wide range of application requirements. A quick and high-pressure jet air cleaning is how the bag cleaning system works. This cleaning method involves sending shock of air through bag or blast, which shatters the dust cake and releases it so it can be disposed of. Since of the quick pulse of air, the system is not often compartmentalized because it enables continuous operation with the fan operating.

Pulse-jet models are the most prevalent kind of industrial dust collectors. This is because these models can be readily tailored, withstand a broad variety of temperatures and pressures, and have a high collecting efficiency. They may be found in almost every industrial setting that involves processing bulk materials, such as those involved in manufacturing chemicals and minerals, food processing plants, and metal fabrication facilities. Pulse-jet collectors may be crafted from various materials.

Cartridge Collectors

Fabric filters may take the form of cartridge collectors, a particular sort of filter developed for specialized use in certain applications. They provide an advantage when a smaller area is needed to accommodate the same airflow volume as a bigger baghouse system. Cartridge collectors fit more fabric areas into smaller spaces, use fewer filter, and allow the filters to be changed from an outside collector, all of which contribute to a reduction in the potential for safety risks. The amount of time necessary to replace the filters and the accompanying labor expenses are also reduced thanks to these characteristics in commercial and industrial settings with extremely fine to light and moderate dust.