Flow conditioning is a process that is conducted by a flow conditioner to improve the accuracy of a flow meter by delivering a consistent flow profile at the sensor position.

The task of flow conditioning is to make sure that the “actual world” environment intimately resembles the “laboratory” atmosphere for the appropriate performance of inferential flow meters.

Flow Meters

Flow meters are commonly characterized in two types:

- Energy extractive

- Energy additive

Energy Extractive Meters

Energy extractive meters require energy in the form of pressure drops. This energy comes from the flowing stream to find the rate of fluid flow. A few examples of this meter are a turbine, vortex, head, and PD meter.

Energy Additive Meters

For flow rate determination, we need to introduce the energy in the flowing system, and this is what the flow meter does. You can observe this system in ultrasonic meters and magnetic meters.

It is important to understand the physical principles of flow metering technology. If these principles are ignored or not understood completely, the Law of Similarity might be desecrated, resulting in high maintenance expenses & incorrect measurement.

Installation Effects

Different installation effects create different flow conditions in the pipe, and the flow meter is greatly affected by where & how they are mounted. Common installation effects are reducers, pipe smoothness/ roughness, tees, valves, and elbows.

It is very important to know how these effects are creating an impact on the flow meter. This impact can cause the upstream installation effects in typical metering design. Flow conditioning is a cost-effective process of creating a flow profile by artificial means. The performance can change if the upstream fittings can disturb the flow profile.

Flow Conditioners

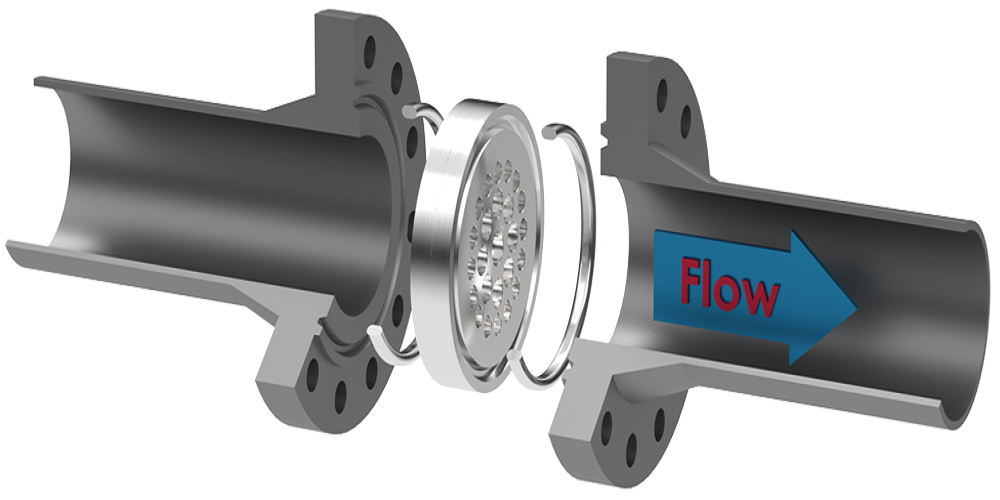

The influence of the fluid dynamics on the performance of the meter can be minimized by installing a flow conditioner in conjunction with straight lengths of pipe to “separate” the meter from upstream piping disturbances.

The separation is never ideal. Nevertheless, the main objective of the conditioner is to generate a "pseudo-fully developed" flow. Check out whmcn flow conditioner to find the top-notch products. This site will provide you with a huge range of fitting instruments and equipment.

Pseudo-Fully Developed Flow

Axisymmetric time, the swirl-free average velocity flow profile, is known as pseudo-fully developed flow. It is defined by the wall prediction power law. However, bear in mind that forces equilibrium is needed to develop the turbulent flow fully. This is important to maintain the cyclic motions of turbulent flow.

To attain the completely developed flow, you need to spend much of your time in a research lab. Certain design objectives are required to attain a separate flow meter. These design objectives are:

- Permanent reduction in pressure loss

- Mechanical design should be durable

- Cost-effective construction solution

- Sensing location/ system should be autonomous

- Complete removal of swirls

- Low contamination

Swirl

Fluid rotation in the pipe is known as swirls. If the pipe direction will change at any point or any other form of blockage can cause swirl. Inflow profile this distortion is unpredictable that can alter by time. The water profile inverts because of centripetal force, which makes the system harder to spin. This local effect can be eliminated with flow conditioning. Flow conditioning will generate a repeatable and reinstate the flow profile symmetry.

Conclusion

It is necessary to understand the physical properties of fluid for designing and operating a precise flow meter application.

Law of Similarity is necessary for designing and operating an accurate fiscal metering facility. Conformity with the separating flow conditioners makes sure the flow field the inferential meter “sees” intimately the laboratory situations.